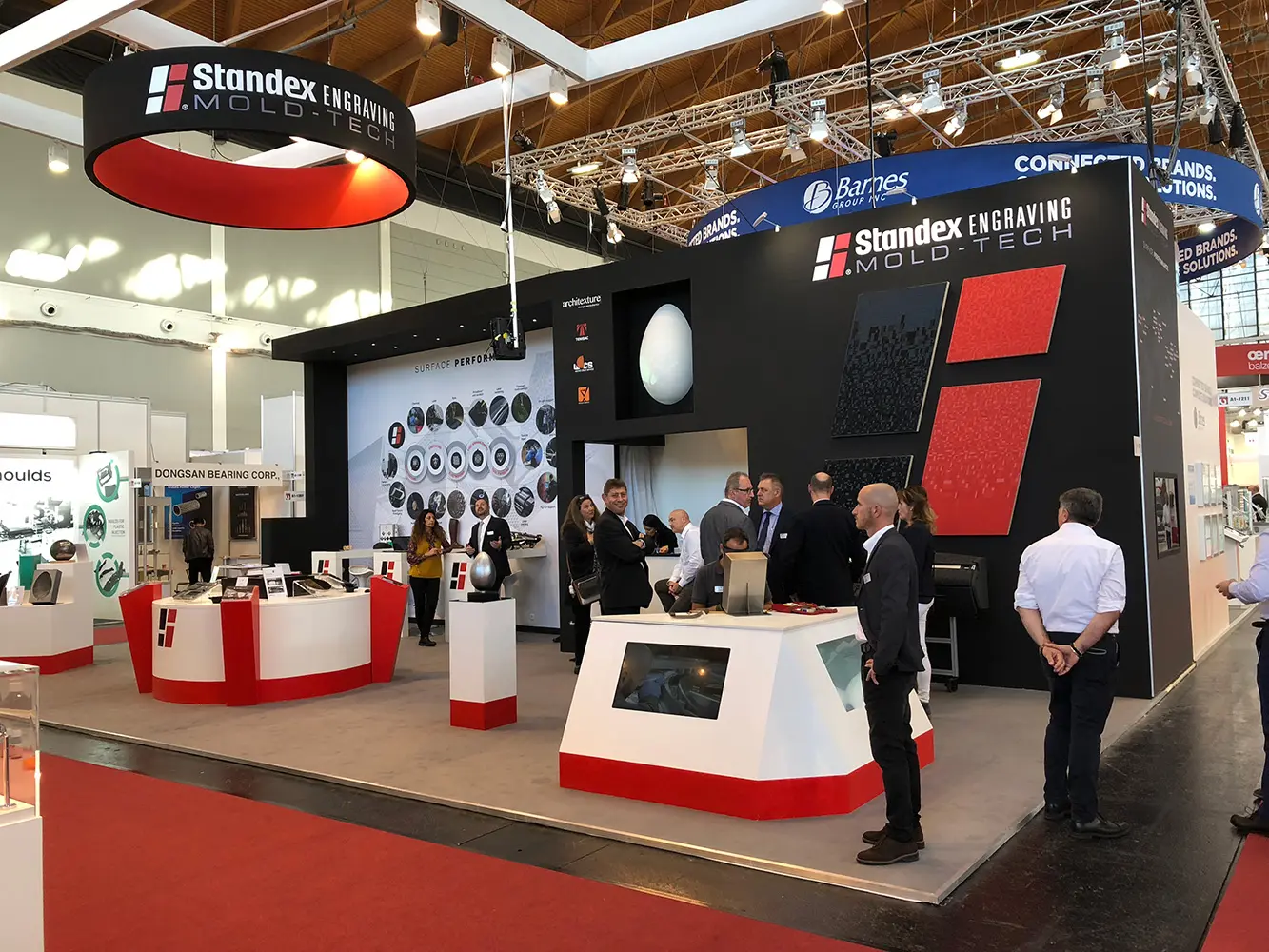

The expertise offered by our architexture consultancy studio takes our clients through the process of Design, Verify and Produce to create a bespoke texture on a model or prototype that can be reviewed and tested in the real world. To explain this process at the recent FAKUMA trade show in Germany, the Standex Engraving Mold-Tech team decided to leave the real world altogether.

Using virtual reality through projection mapping technology, visitors could select one of several textures and watch it be engraved with light on a two-meter egg. Once engraved, the virtual egg rotated to genuinely fool the eye, completing the entire process in roughly one minute.

A touch-screen invited visitors to begin the process with a 3D-scan of the object, create a mesh layout on the egg’s surface, then select a custom texture. Looking up at the half-egg mounted on the trade show facade, the texture would sweep across the surface in arched passes of vivid detail until complete. Then when it began to rotate, visitors witnessed how every facet was perfectly proportional with no distortion. A special thank you goes out to Thorsten Miebach, Deputy Managing Director, Germany, and his team at Standex Engraving Mold-Tech in Krefeld, Germany for their innovative creativity.